Thermaltake Pacific RL240 White Edition

The Thermaltake Pacific RL White Edition introduces high-quality radiators to deliver outstanding water cooling performance for the enthusiast’s PC. Manufactured from high-quality German zinc alloy aluminum and aerospace-grade materials, configurations of 120mm, 240mm, and 360mm are available to provide exceptional performance. Integrated G1/4" threads make it easy to install, while rigid connections ensure leak-resistant measures are in place. With an ideal mounting, fitting and flow set-up, the Thermaltake Pacific RL White Edition meets your cooling needs in every way.

Tt LCS Certified

Tt LCS Certified is a Thermaltake exclusive certification applied only to products that pass the design and hardcore enthusiasts standards that a true LCS chassis should hold to. The Tt LCS certification was created so that we at Thermaltake can indicate to all power users which chassis have been tested to be best compatible with extreme liquid cooling configurations, ensuring you get the best performance from the best features and fitment.

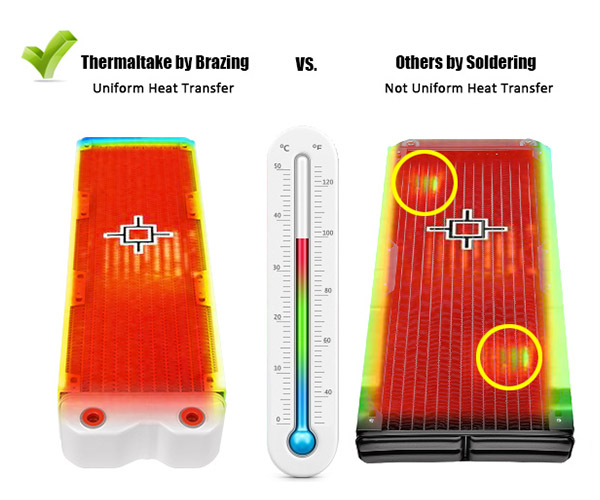

Optimized Heat Dispatching

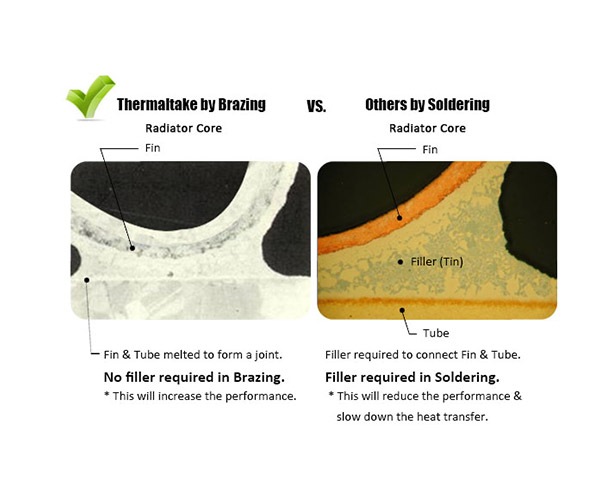

Designed for the most demanding hardcore enthusiasts, the Thermaltake R Series Radiators are optimized for maximum heat dispatching. They deliver an average heating load of 32℃-35℃ on each radiator. After brazing, the fin and tube connect to form a joint, thereby creating uniform heat transfer. By efficiently pulling heat away from the power-dissipating components, the radiators ensure component reliability.

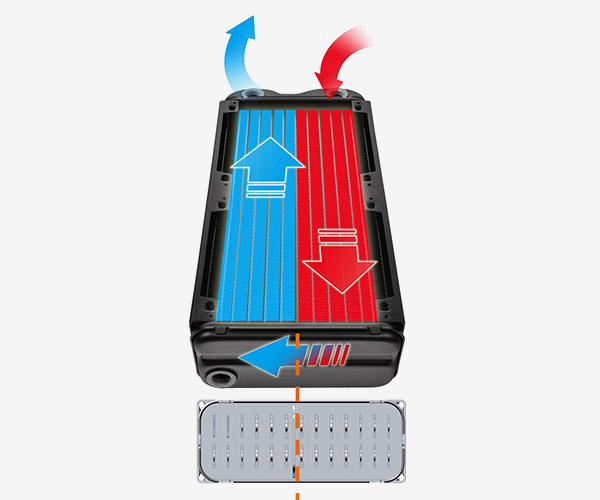

Slim Form Factor Design

The Pacific R Series is a slim radiator with a 13-set flat tube design to increase heat transfer. Water flows down on the one side, then circulates back to the other side of the radiator.

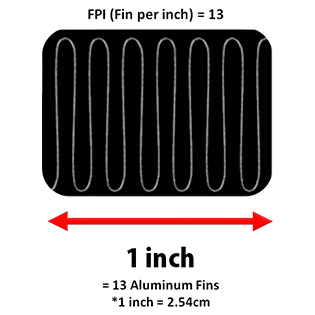

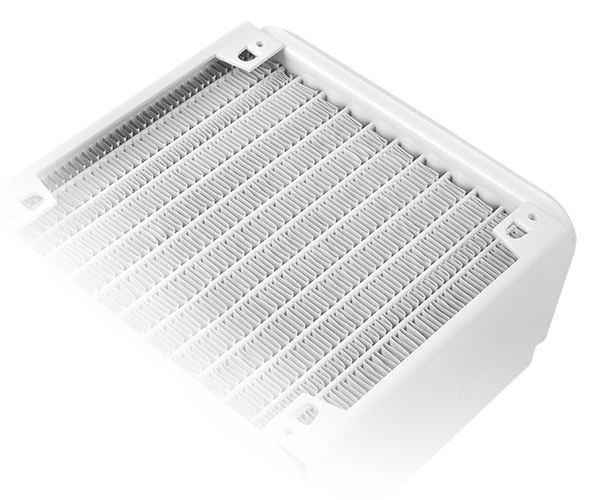

High-Density Fin Design

Fin density is optimally designed to accommodate high air pressure. The cooling performance improves significantly with increased fan speed, offering exceptional cooling performance during operation. FPI (fin per inch): 17.

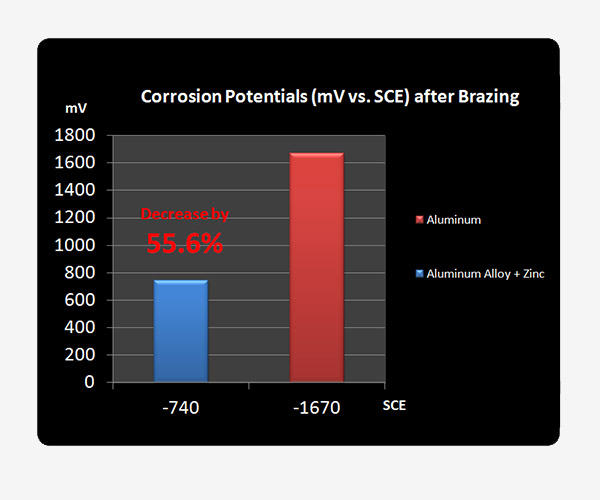

German-Made Anti-Corrosion Materials

Without compromise, the Pacific R Radiator Series is designed with high-quality German aerospace-grade materials and constructed with zinc, the most common anti-corrosion agent. Although this protection will gradually degrade as the zinc corrodes away over time, it provides the best means to reduce electronic conductivity and can withstand scratches to the zinc layer. Corrosion potentials of zinc alloy aluminum can be reduced by 55.6% after brazing.

High-Quality Manufacturing Process: Brazing

An exceptional manufacturing process using high temperature brazing at 1022℉/550℃ sets Pacific R Radiator Series in a class of their own. This technique allows for impurities to be kept out of the brazing process, ensuring that full strength on all the connected areas is achieved. The radiators are baked through a controlled atmosphere brazing line. The materials melt into each other to accomplish optimal thermal transfer from the tubes to the actual fins in order to attain better heat evacuation

Radiator Production Process Video

Remarkable Expansion

The Pacific RL Radiator Series provides multiple sizes for users to build the ultimate in custom configurations. A wide array of radiator sizes are available for enthusiasts to build up aesthetically-superior water cooling systems by allocating the radiators to each particular component and incorporating externally-modular upgrades for their chassis.

Cautions

Thermaltake recommends the following steps to be taken before using the Pacific series radiators and water blocks

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant, it may harm your loop and reduce performance.

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse and dry. This will ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after completing your water loop setup

- It is strongly recommended to use market proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while preventing the entire cooling system – copper, brass, nickel, aluminum, and steel – from corrosion.

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushing the coolant into the loop.

- DO NOT let the pump run dry, when there is no liquid entering the pump turn off your power immediately

- Fill the reservoir to the top as it will prevent air from going into the pump

- If necessary tilt the system slightly from side to side to bleed the air out of the loop.

- Place some paper towels under fittings and joining points to test for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed the air out of the loop.

Cautions

Thermaltake recommends the following steps to be taken before using the Pacific series radiators and water blocks:

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant, it may harm your loop and reduce performance.

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000, which offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse, and dry. This will ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after completing your water loop setup:

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000, which offers great performance while preventing corrosion in the entire cooling system (copper, brass, nickel, aluminum, and steel).

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushes the coolant into the loop.

- DO NOT let the pump run dry. If no liquid is entering the pump, turn off your power immediately.

- Fill the reservoir to the top to prevent air from entering the pump.

- If necessary, tilt the system slightly from side to side to bleed the air out of the loop.

- Place paper towels under fittings and joining points to test for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed the air out of the loop.

- Before starting, flush out your system properly to prevent any coolant or unwanted particles from sticking to your tubes, radiators, and other cooling components.

- Coolant might fade over time.

| P/N | CL-W012-AL00WT-B |

|---|---|

| Dimensions |

282.5 (L) x 129 (W) x 64 (H) |

| Weight |

836 g |

| MATERIAL |

Anti-Corrosion Aluminum Alloy |

| FPI (Fin per inch) |

14 |

| FLAT TUBE |

13 set |

| Parts |

Stopper * 3 (G 1/4 ) |

| Screw thread |

G 1/4 * 5 |

User Manual

- File Name

- Description

- Size

- Version

- Release Date